You are here: Home1 / Resource2 / Technical Guidance3 / How to Select the Right Hydraulic Hose for Your Application?

How to Select the Right Hydraulic Hose for Your Application?

Selecting the appropriate hydraulic hose is of vital importance for ensuring the safety, efficiency and long-term stability of the hydraulic system. During our 16 years of foreign trade experience at Utigoflex, we have witnessed that many companies have suffered losses due to incorrect selection of hoses – ranging from frequent leaks and pressure losses leading to low efficiency, to serious safety accidents and high downtime costs caused by sudden bursts.

Utigoflex is well aware that hydraulic hoses are by no means uniform products. This guide, based on the industry STAMP principles, provides a systematic decision-making framework for engineers and purchasing managers, enabling you to accurately identify the best solution for specific applications.

Understand Application Requirements

First, determine how and where the hose will be used. Consider equipment type, motion characteristics, vibration intensity, and whether the hose will operate indoors or outdoors.

Common Equipment Types and Application Insights:

- Heavy machinery (excavators, bulldozers): Typically requires multi-layer steel braided or spiral-reinforced hoses (e.g., EN 856 4SP/EN856 4SH).

- Hydraulic presses, automated production lines: Emphasize bend radius and lightweight design; may require thermoplastic or highly flexible hoses (e.g., SAE 100 R7/SAE 100 R8).

- General industrial hydraulic presses: Steel braided hoses are most commonly used (e.g., SAE 100 R1/EN 853 1SN or SAE 100 R2 / EN 853 2SN).

- Let us know your specific application to help us provide a more precise solution.

How to Choose the Right Hydraulic Hose

Working Pressure and Safety Factor

Always select a hose with a working pressure higher than system requirements. A proper safety factor and sufficient burst pressure help prevent unexpected failures.

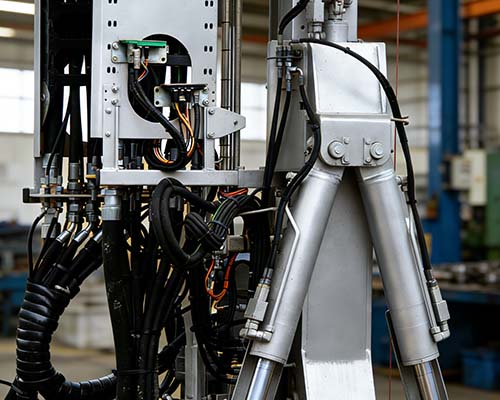

equipment operation

Typical Example:

- SAE 100 R1 Maximum Working Pressure: 25 mpa / 3625 psi

- SAE 100 R9 Maximum Working Pressure: 31.5 mpa / 4570 psi

- SAE 100 R6 maximum working pressure: 3.5 mpa / 510 psi

How to Choose the Right Hydraulic Hose

Material and Temperature Compatibility

Given the varying properties of rubber, thermoplastic, and PTFE hoses, ensuring material compatibility with the conveyed medium is one of the most critical factors in hose selection. Incompatible materials can lead to performance degradation, leaks, or even contamination.

For example, Some synthetic hydraulic oils or water-based hydraulic oils may have a corrosive effect on standard nitrile rubber (NBR).For extreme chemicals or high-temperature applications, PTFE hoses are a more reliable choice.

How to Choose the Right Hydraulic Hose

Hose Size and Bend Radius

Selecting the appropriate hose size is essential for ensuring optimal flow rates and minimizing pressure loss. Undersized hoses increase internal friction and restrict flow, while oversized hoses incur unnecessary costs. Additionally, the minimum bending radius must be considered to prevent premature wear and cracking.

Standards and Durability

Verify compliance with SAE, EN, or ISO standards. Resistance to abrasion, UV exposure, and harsh environments extends hose lifespan.

- Standard Compliance: Utigoflex products strictly adhere to internationally recognized standards: EN853, EN856, EN 1762, or SAE J517.

- Abrasion Resistance: For demanding applications, Utigoflex offers hydraulic hoses with ozone resistance, UV resistance, and high abrasion resistance.

- Quality Assurance: Utigoflex’s hose manufacturing process is ISO 9001:2015 certified and holds multiple authoritative certifications including MSHA, REACH, RoHS, and FDA.

Conclusion

Selecting the right hydraulic hose for your application requires rigorous evaluation of multiple technical parameters. By following the STAMP principle, you can systematically narrow your selection to ensure the optimal balance of performance, safety, and cost-effectiveness.

We are ready to serve you! Whether your current application involves high-pressure pulsation, high abrasion resistance, or complex piping systems with strict bending radius requirements, please feel free to share your specific needs. You can browse our hydraulic product range at any time. If you have specific requirements or are unsure which products suit your needs, we welcome you to contact us for the optimal hydraulic hose solutions.

byadministratorKathy/February 3, 2026