You are here: Home1 / Resource2 / Technical Guidance3 / How to Choose Rubber Hose for Different Fluids

How to Choose Rubber Hose for Different Fluids

1. Understand the Type of Fluid

The first step is to identify the type of fluid to be conveyed. Common fluid categories include water, air, oils, fuels, chemicals, and food-grade liquids.

The physical and chemical properties of different fluids vary significantly. Therefore, it is essential to match the appropriate hose liner material to prevent issues such as hose aging, corrosion, or fluid absorption caused by material incompatibility.

The most commonly conveyed fluid types are categorized as follows:

- General water-based fluids

Includes tap water, industrial cooling water, boiler feedwater, etc., with stable chemical properties.

Suitable Hoses: Rubber hoses (natural rubber, styrene-butadiene rubber), PVC hoses. Must withstand normal pressure and temperature. For food-grade applications (e.g., drinking water), select rubber or silicone hoses compliant with FDA standards. - Oil-Based Fluids

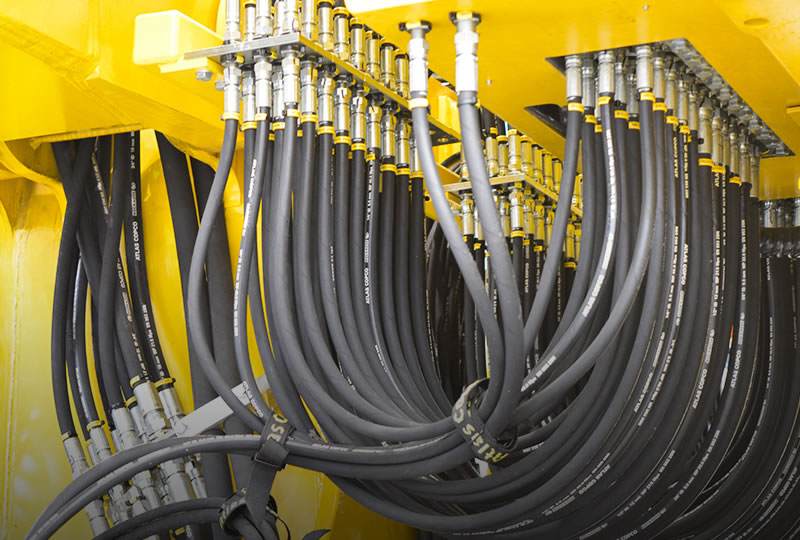

Includes hydraulic oil, lubricating oil, diesel, gasoline, engine oil, etc., characterized by high permeability and lubricity.

Suitable Hoses: Nitrile rubber (NBR) hoses, fluorocarbon rubber (FKM) hoses. Hydraulic systems require high-pressure hydraulic hoses with steel braid reinforcement, clearly marked with oil resistance rating and pressure rating (e.g., 40MPa). Gasoline transfer requires additional anti-static design considerations. - Chemically Corrosive Liquids

Includes acid/alkali solutions (sulfuric acid, hydrochloric acid, sodium hydroxide), organic solvents (methanol, ethanol, acetone), salt solutions, etc., exhibiting strong corrosive and oxidative properties.

Suitable Hoses: Fluorocarbon (FKM), PTFE (polytetrafluoroethylene) hoses. Ordinary rubber hoses are strictly prohibited. Select inner lining material based on chemical concentration and temperature. For example, use PTFE-lined hoses with stainless steel braiding for concentrated acid transfer. - Food-Grade Liquid Fluids

Includes milk, juice, edible oils, sauces, etc., requiring non-toxic, odorless, and contamination-free properties.

Suitable hoses: Food-grade silicone hoses, EPDM rubber hoses. Must be FDA, LFGB, or equivalent certified. Hose inner walls must be smooth with no residue for easy cleaning and sterilization. - Gaseous Fluids

Prioritize airtightness, pressure resistance, and static dissipation during transport to prevent gas leaks or explosion risks. - Ordinary Gases

Includes compressed air, nitrogen, oxygen, carbon dioxide, etc., primarily used in industrial power, welding, and packaging applications.

Suitable Hoses: Polyurethane (PU) hoses, EPDM rubber hoses. Oxygen transport requires oil-free, degreased hoses to prevent grease-induced combustion. High-pressure gases (e.g., high-pressure nitrogen) necessitate pressure-resistant hoses with fiber or steel reinforcement layers. - Flammable and Explosive Gases

Includes natural gas, liquefied petroleum gas (LPG), acetylene, hydrogen, etc., classified as high-risk fluids.

Recommended Hoses: Chloroprene rubber (CR) hoses, fluorocarbon rubber hoses. Must possess anti-static and flame-retardant properties. Outer layer requires conductive layer design with grounding. Acetylene hoses must be marked for backfire resistance. - Slurry / Solid-liquid mixtures

Includes mortar, mineral slurry, mud, food sauces (containing particles), chemical slurries, etc., characterized by high viscosity and abrasiveness.

Recommended Hoses: Abrasion-resistant rubber hoses (e.g., neoprene, butyl rubber) or polyurethane abrasion-resistant hoses. Select constructions with abrasion-resistant liners + multi-ply braided reinforcement. Slurry hoses for mining and construction applications must additionally specify abrasion resistance indices (e.g., Abecrombie abrasion value).

2. Choose the Right Inner Tube Material

- Natural Rubber (NR)

Suitable Fluids:

Ordinary water, industrial cooling water, low-concentration acid/alkali solutions (concentration <5%), air, inert gases (nitrogen, argon), vegetable/animal oils (non-food grade). Unsuitable Fluids: Gasoline, diesel, organic solvents, high-concentration acids/alkalis, mineral oils. Typical Applications: Construction site water supply, agricultural irrigation, general pneumatic equipment connections. - Nitrile Rubber (NBR)

Core Characteristics: Excellent oil and solvent resistance

Suitable Fluids:

Hydraulic oil, lubricating oil, diesel, gasoline, engine oil, mineral oil, low-concentration acid/alkali solutions, alcohols (methanol, ethanol, concentration <30%). Unsuitable Fluids: Strongly polar solvents (acetone, ethyl acetate), aromatic hydrocarbons (benzene, toluene), high-concentration acids/alkalis. Typical Applications: Hydraulic system hoses, construction machinery oil lines, automotive fuel transfer hoses. - Ethylene Propylene Diene Monomer (EPDM)

Core Properties: Superior weather resistance, ozone resistance, steam resistance, acid/alkali resistance

Suitable Fluids:

Hot water, steam (temperature ≤150°C), high-concentration acid/alkali solutions (sulfuric acid, sodium hydroxide, etc.), coolants, ethylene glycol, detergents, drinking water (food-grade EPDM).

Unsuitable Fluids:

Gasoline, diesel, mineral oils, organic solvents.

Typical Applications: Boiler steam conveyance, chemical acid/alkali transport, hot water conveyance in food processing. - Polytetrafluoroethylene (PTFE)

Core Properties: Exceptional chemical inertness, high-temperature resistance, non-stick properties

Suitable Fluids:

Virtually all chemical fluids, including strong acids (concentrated nitric acid, concentrated sulfuric acid), strong alkalis (concentrated sodium hydroxide), organic solvents, strong oxidizing agents, high-temperature fluids (≤260°C), and food-grade fluids (milk, fruit juice, edible oils).

Unsuitable Fluids:

Molten alkali metals, fluorine gases (extremely special conditions).

Typical Applications: High-end chemical corrosion fluid transfer, food and pharmaceutical industry fluid transfer, high-temperature fluid sealing hoses. - Polyurethane (PU)

Core Characteristics: Abrasion resistance, hydrolysis resistance, excellent flexibility

Suitable Fluids:

Water, compressed air, inert gases, low-concentration acids/alkalis, lubricating oils (select grades), food-grade fluids (requires food-grade certification).

Unsuitable Fluids:

Gasoline, diesel, organic solvents, high-temperature fluids (>80°C).

Typical Applications: Pneumatic tool hoses, light-duty conveyance tubing in food processing, abrasion-resistant slurry conveyance in mining. - Polyvinyl Chloride (PVC)

Core Characteristics: Low cost, acid/alkali resistance, lightweight

Suitable Fluids:

Tap water, industrial cooling water, low-concentration acid/alkali solutions, air, non-potable liquids.

Unsuitable Fluids:

Gasoline, diesel, organic solvents, high-temperature fluids (>60°C), food-grade fluids.

Typical Applications: Domestic water supply hoses, industrial light-duty drainage hoses, ventilation hoses.

3. Consider Temperature and Pressure

Fluid temperature and operating pressure directly affect hose performance. High temperatures or pressure spikes require hoses designed with reinforced layers and suitable rubber compounds.

| Fluid Temperature Range | Suitable Hose Material | Typical Application Scenarios |

| Low Temperatures (-40°C To 0°C) | Silicone Rubber, Fluorocarbon Rubber, Polyurethane | Low-Temperature Coolant, Liquid Nitrogen Transfer |

| Ambient Temperature (0°C To 80°C) | Natural Rubber, Nitrile Rubber, PVC | Tap Water, Hydraulic Oil, Compressed Air |

| High Temperature (80°C To 200°C) | EPDM Rubber, Fluororubber | Steam, High-Temperature Thermal Oil, High-Temperature Chemical Liquids |

| Ultra-High Temperature (>200°C) | Polytetrafluoroethylene (PTFE), Special Fluorinated Rubber | High-Temperature Molten Resin, High-Temperature Corrosive Gases |

4. Check Standards and Safety Requirements

Many industries require compliance with standards such as SAE, EN, or FDA for food-grade applications. Always verify certification before selection.

- SAE (Society of Automotive Engineers)

SAE standards serve as authoritative technical specifications in the industrial hydraulic hose sector, rigorously defining core performance metrics such as pressure ratings, burst pressure, temperature tolerance ranges, and pulse fatigue life for hydraulic hoses and assemblies. Sub-standards like SAE 100 R1AT and SAE 100 R2AT correspond to hydraulic hoses with distinct reinforcement layer structures. - EN (European Norm)

A unified technical standard for industrial products implemented across the European Union. It provides detailed classifications for industrial hose categories, with specific standards corresponding to different hose applications. For example:

– EN 853 specifies technical requirements for hydraulic hoses and assemblies. EN 1360 defines safety metrics for rubber hoses in food contact applications, while EN 14501 specifies gas-tightness and anti-static properties for gas delivery hoses. Compliance with EN standards serves as the fundamental threshold for industrial hoses entering EU member markets, ensuring performance and safety conformity across the European Union. - FDA

FDA (U.S. Food and Drug Administration) certification is the core safety qualification for industrial hoses used in food and pharmaceutical contact applications. This certification focuses on testing the inner lining materials (such as food-grade silicone, EPDM, PTFE, etc.) for non-toxicity, odorlessness, and absence of harmful substance migration. It strictly limits the content of harmful components like heavy metals and plasticizers. Hoses certified by the FDA can be legally used in scenarios such as food processing (e.g., milk and juice transfer), and pharmaceutical production (e.g., drug solution transfer). It serves as an essential passport for accessing premium food and pharmaceutical markets in North America and globally. - ISO9001:2015

ISO9001:2015 is a quality management system standard established by the International Organization for Standardization. It does not directly regulate the product performance of industrial hoses but instead establishes systematic requirements for quality management across the entire enterprise operation—from raw material procurement and production processing to finished product inspection and after-sales service. Companies holding this certification demonstrate the capability to consistently produce compliant industrial hoses, effectively reducing product quality fluctuation risks and significantly enhancing foreign trade customers’ confidence in the stability of the enterprise’s supply chain and product quality. - CE

CE (European Conformity) certification is the mandatory access mark for industrial hoses entering the EU market. All industrial hoses intended for circulation within EU member states must comply with relevant EU Health, Safety, and Environmental (HS&E) directives. Typically, this requires product testing against corresponding EN standards to demonstrate the absence of safety hazards. Industrial hoses bearing the CE mark can circulate freely across all EU member states, serving as the core credential for obtaining market access in the EU.

5. Evaluate the Operating Environment

External factors like abrasion, UV exposure, and weather conditions influence hose lifespan. Choosing a hose with a resistant outer cover helps extend service life.

6. Conclusion

Selecting the appropriate rubber hose for various fluids requires understanding fluid properties, material compatibility, and operating conditions. Proper selection enhances safety, efficiency, and long-term performance in industrial applications. Based on years of manufacturing experience and serving numerous customers, Utigoflex has compiled the following table to help you quickly understand and choose the right hose.

| Fluid Category | Common Fluid Examples | Recommended Hose Materials | Core Performance Requirements | Applicable Industry Scenarios | Selection Notes |

| Neutral & Low-corrosive Fluids | Tap water, industrial pure water, hydraulic oil, lubricating oil, diesel, kerosene | Steel wire braided/wound rubber hydraulic hose, PVC hose, PU hose | Pressure resistance, wear resistance, temperature resistance (-40℃~120℃), weather resistance | Construction machinery, machine tool lubrication, agricultural irrigation, fuel delivery | Choose steel wire reinforced structure for high-pressure applications to prevent hose burst |

| Acid Corrosive Fluids | Hydrochloric acid, sulfuric acid, acetic acid, citric acid, electroplating solution | PTFE hose, FKM hose, EPDM hose | Acid corrosion resistance, impermeability, high temperature resistance (PTFE up to 260℃) | Chemical production, electroplating plants, pickling workshops | PTFE is preferred for high-concentration strong acids to avoid rubber swelling |

| Alkali Corrosive Fluids | Sodium hydroxide, potassium hydroxide, ammonia water, detergent solution | EPDM hose, CR hose, PTFE hose | Alkali corrosion resistance, aging resistance, resistance to hardening and embrittlement | Chemical cleaning, sewage treatment, papermaking industry | Avoid NBR hose which is susceptible to alkali erosion |

| Solvent-based Fluids | Alcohol, acetone, toluene, xylene, gasoline diluent | PTFE hose, FKM hose | Solvent swelling resistance, low permeability, excellent sealing performance | Coating production, ink manufacturing, chemical solvent transportation | Never use ordinary rubber hoses which can be dissolved by solvents and cause leakage |

| Food-grade Fluids | Drinking water, milk, fruit juice, edible oil, beer, syrup | Food-grade silicone hose, food-grade PU hose, food-grade PTFE hose | Compliance with FDA/LFGB certification, odorless, easy to clean, sterilizable | Food processing, beverage production, dairy industry | Regular cleaning and disinfection to prevent bacterial growth from residues |

| Hygienic-grade Fluids | Pharmaceutical intermediates, medicinal liquid, plasma, sterile water | Platinum-cured silicone hose, hygienic-grade PTFE hose | Sterile, no extractables, resistance to steam sterilization (121℃) | Pharmaceutical factories, biopharmaceuticals, laboratories | Match with hygienic-grade clamp joints to avoid thread contamination |

| Gaseous Fluids | Compressed air, nitrogen, natural gas, liquefied petroleum gas (LPG), steam | High-pressure steel wire reinforced rubber hose (for natural gas), EPDM hose (for steam), anti-static PU hose | Air tightness, high pressure/high temperature resistance, anti-static (for flammable and explosive gases) | Pneumatic equipment, gas transportation, steam cleaning | Add anti-static layer for gas delivery; steam hoses should have temperature resistance ≥150℃ |

| Solid-liquid Mixed Fluids (with particles) | Ore slurry, concrete, mortar, tomato sauce, chemical slurry | Wear-resistant NBR hose, PU corrugated hose, fabric-reinforced rubber hose | High wear resistance, tear resistance, extrusion resistance | Mining and metallurgy, construction engineering, food sauce processing | Choose corrugated structure for large-caliber applications to reduce fluid resistance |

Utigoflex is committed to providing customers with high-quality, high-performance hose products. Through continuous innovation and technical expertise, we solve fluid transfer challenges across industries to create greater value. If you remain uncertain about selecting the right industrial rubber hose, please contact us for professional guidance. Click Contact Us!

byadministratorKathy/February 24, 2026